Loctite adhesives are widely used across various industries, from electronics and automotive to medical devices and industrial assembly. However, the effectiveness of these adhesives heavily depends on the right dispensing equipment. Choosing the best Loctite dispensing system ensures precision, reduces waste, improves efficiency, and maintains product quality.

This guide will help you determine the most suitable Loctite dispensing equipment for your specific needs by considering key factors like adhesive type, application method, volume requirements, and automation levels.

Understanding Loctite Dispensing Equipment

Loctite dispensing equipment is designed to deliver adhesives accurately and consistently. These systems range from manual dispensers to fully automated robotic dispensing units. The right choice depends on factors such as application precision, production volume, and adhesive characteristics.

Types of Loctite Dispensing Equipment

- Manual Dispensers

- Best for low-volume applications.

- Typically consists of squeeze bottles, syringes, or hand-held applicators.

- Suitable for small-scale production or prototype development.

- Loctite Pro Pump Handheld Dispenser

- Pneumatic Dispensers

- Use air pressure to dispense adhesives with controlled precision.

- Ideal for moderate-volume applications that require consistency.

- Common in assembly lines for electronics, automotive, and medical devices.

- Volumetric Dispensers

- Utilize positive displacement technology for highly accurate dispensing.

- Essential for applications requiring precise adhesive volume control.

- Frequently used in microelectronics and medical industries.

- Loctite EQ PU20

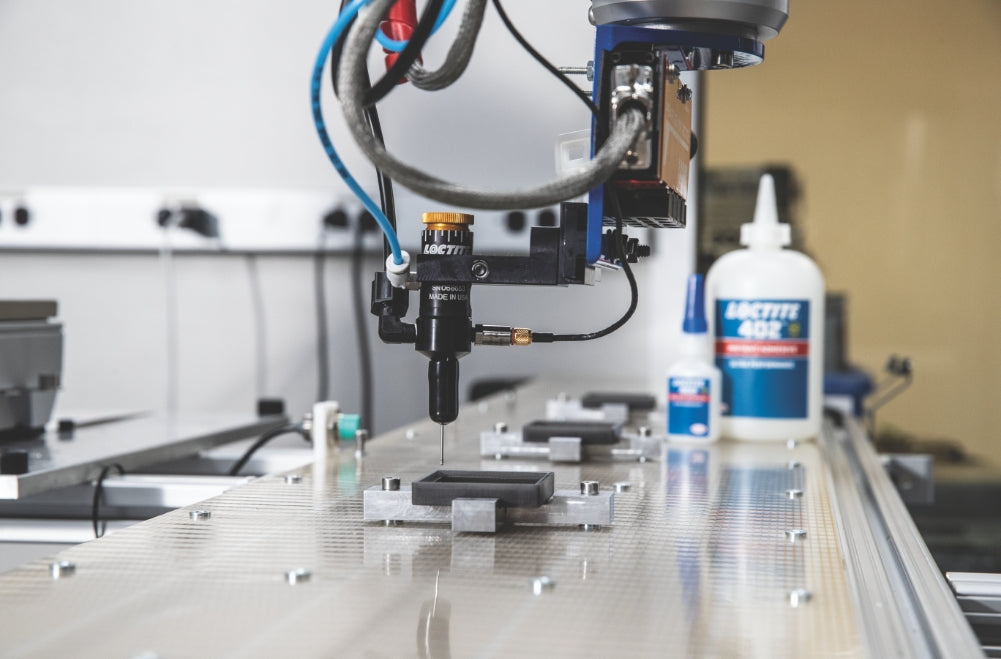

- Automated Dispensing Systems

- Integrate robotics for high-speed, consistent adhesive application.

- Ideal for large-scale production with strict quality control requirements.

- Often used in automotive assembly, aerospace, and consumer electronics manufacturing.

Factors to Consider When Choosing Loctite Dispensing Equipment

1. Type of Loctite Adhesive

Different Loctite adhesives have unique viscosity levels, curing mechanisms, and application requirements. Selecting the right dispensing equipment depends on the adhesive being used:

- Anaerobic Adhesives (e.g., threadlockers, gasketing)

- Require precision dispensing to avoid excess application.

- Best dispensed using pneumatic or volumetric dispensers.

- Cyanoacrylates (Instant Adhesives)

- Low viscosity; requires controlled droplet dispensing.

- Suitable for manual, pneumatic, or automated dispensing systems.

- Epoxies and Structural Adhesives

- High viscosity

- Common in high-strength bonding applications.

- Suitable for manual dispensing

- UV-Curing Adhesives

- Need precision dispensing and UV exposure for curing.

- Often used in medical and electronics manufacturing.

- Best dispensed using manual or automated dispensing systems.

2. Production Volume & Speed

The scale of production plays a significant role in equipment selection:

- Low-volume applications → Manual or pneumatic dispensers.

- Medium-volume applications → Pneumatic or volumetric systems.

- High-volume applications → Automated dispensing with robotics for efficiency.

3. Precision and Accuracy Needs

Some applications require extremely precise adhesive placement, especially in microelectronics and medical devices. In such cases, volumetric and automated dispensers are preferred over manual or pneumatic options.

4. Integration with Existing Production Line

For manufacturing facilities, it's essential to choose dispensing equipment that seamlessly integrates with existing automation systems. Robotic and programmable dispensers work well in synchronized production lines.

5. Cost and Maintenance Considerations

- Manual dispensers have lower upfront costs but may lead to inconsistencies.

- Pneumatic dispensers provide cost-effective automation for moderate production.

- Volumetric and robotic systems require higher investment but offer long-term savings through precision and efficiency.

Key Benefits of Choosing the Right Loctite Dispensing Equipment

- Improved Efficiency: Reduces material waste and speeds up production.

- Consistent Application: Ensures uniform adhesive distribution for reliable bonding.

- Reduced Costs: Minimizes excess adhesive use and prevents defects.

- Enhanced Product Quality: Eliminates errors caused by manual application.

Conclusion

Selecting the right Loctite dispensing equipment is essential for achieving precision, efficiency, and cost-effectiveness in adhesive applications. By considering adhesive type, production volume, precision needs, and automation requirements, you can optimize your dispensing process and improve overall manufacturing performance.

Whether you need a simple manual applicator for small projects or an advanced robotic dispensing system for large-scale production, making the right choice will ensure seamless and reliable adhesive application. Enquire with us if you are still unsure which dispensing solutions you require!

Leave a comment

All comments are moderated before being published.

Situs ini dilindungi oleh reCAPTCHA dan berlaku Kebijakan Privasi dan Persyaratan Layanan Google.