Are you tired of dealing with loose screws or bolts that always seem to come undone? If so, finding the right threadlocker is essential. In this guide, we will explore the age-old debate of red vs blue threadlockers to help you make the right choice for your projects.

What is threadlocker and why is it important?

Threadlocker is a type of adhesive that is used to secure threaded fasteners such as screws, bolts, and nuts. It is typically applied to the threads of the fastener before it is tightened, creating a strong and reliable bond. The primary purpose of threadlocker is to prevent the fasteners from loosening due to vibration, temperature changes, or other external factors.

Using threadlocker is important for several reasons. First and foremost, it ensures the integrity of your assembly by keeping the fasteners tightly secured. This is especially crucial in applications where failure or loosening of the fasteners could have serious consequences, such as in automotive or aerospace industries. Additionally, threadlocker helps to extend the lifespan of your equipment by minimizing wear and tear caused by loose fasteners.

Understanding the different types of threadlockers - red and blue

When it comes to threadlockers, two of the most common options are red and blue. While they may look similar, these threadlockers differ in terms of their strength and applications.

Red threadlocker, also known as high-strength threadlocker, is designed to create a permanent bond. Once applied and cured, it becomes extremely difficult to disassemble the fasteners without the use of heat or specialized tools. Red threadlocker is ideal for heavy-duty applications that require a strong and secure connection, such as in heavy machinery, construction, or industrial equipment.

Blue threadlocker, also known as medium-strength threadlocker, offers a more versatile solution. Unlike red threadlocker, blue threadlocker allows for easy disassembly of the fasteners when required. It provides enough strength to prevent loosening, but can still be loosened with hand tools when necessary. Blue threadlocker is commonly used in applications that may require future adjustments or repairs, such as in automotive, plumbing, or electrical work.

Factors to consider when choosing between red and blue threadlockers

When deciding between red and blue threadlockers, there are several factors to consider:

1. Application: Consider the specific requirements of your project. If you need a strong and permanent bond, red threadlocker is the way to go. However, if you anticipate the need for future adjustments or repairs, blue threadlocker may be a better choice.

2. Strength: Evaluate the level of strength needed for your application. Red threadlocker provides a higher level of strength, while blue threadlocker offers medium strength. Consider the forces and stresses that will be exerted on the fasteners and choose accordingly.

3. Disassembly: Think about whether you will need to disassemble the fasteners in the future. If so, blue threadlocker is the more suitable option as it allows for easier removal using hand tools.

4. Temperature and environment: Take into account the temperature and environmental conditions that the threadlocker will be exposed to. Red threadlocker is typically more resistant to extreme temperatures and harsh environments than blue threadlocker, making it more suitable for less demanding conditions.

5. Expert recommendations: Seek advice from professionals or experts in the field. They can provide valuable insights based on their experience and knowledge of different applications.

By carefully considering these factors, you can make an informed decision and choose the right threadlocker for your specific needs.

Best practices for applying red and blue threadlockers

To ensure the effectiveness and longevity of your threadlocker application, it is important to follow these best practices:

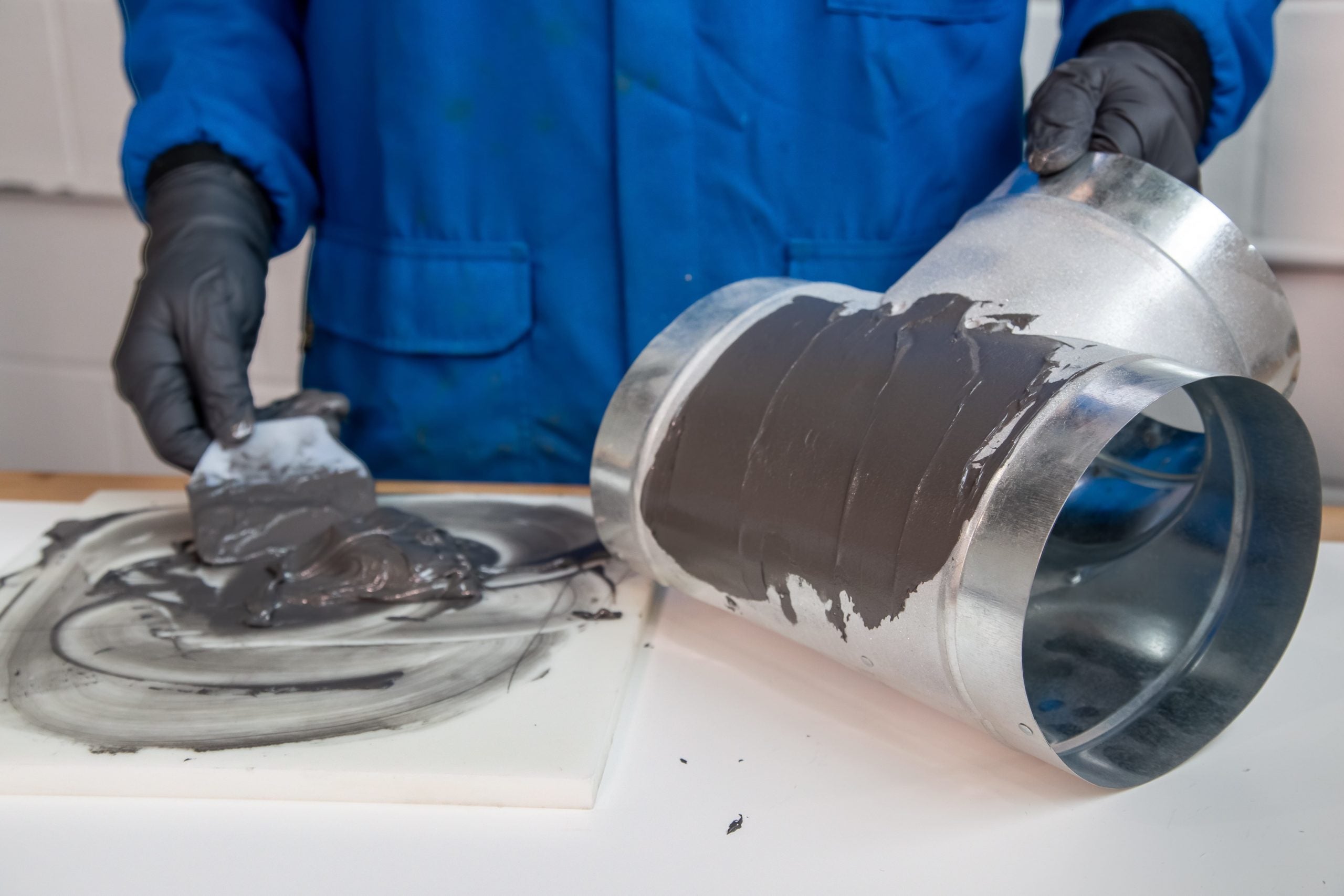

1. Clean and dry surfaces: Before applying the threadlocker, make sure that the surfaces are clean and free from any oil, grease, or debris. Use a suitable cleaning agent to remove any contaminants and ensure proper adhesion.

2. Apply sparingly: Apply the threadlocker sparingly to the threads of the fastener. A small amount is usually sufficient to create a strong bond. Applying too much threadlocker can result in excess adhesive flowing out and potentially causing issues.

3. Allow proper curing time: After applying the threadlocker, allow sufficient time for it to cure. Follow the manufacturer's instructions for recommended curing time, which can vary depending on the specific product and application.

4. Tighten properly: Tighten the fastener to the recommended torque value. This will ensure that the threadlocker is evenly distributed and the bond is properly formed.

Following these best practices will help maximize the effectiveness of your threadlocker application and ensure a secure connection.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.