In industrial environments, equipment faces constant wear and tear due to factors like abrasion, corrosion, and chemical exposure. Devcon Brushable Ceramic Coating is a highly durable, epoxy-based protective solution designed to safeguard metal surfaces and extend their operational lifespan. It creates a smooth, non-porous barrier that enhances efficiency, reduces maintenance costs, and improves overall performance.

This article explores the best applications for Devcon Brushable Ceramic Coating and how it benefits industries such as manufacturing, marine, and chemical processing.

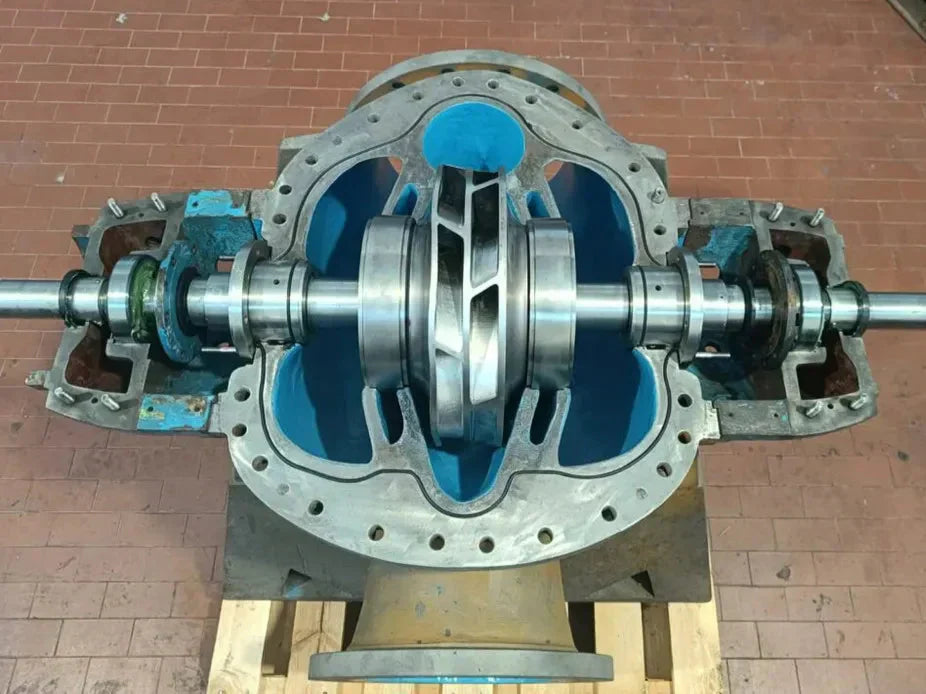

1. Pump and Valve Protection

Application:

Pumps and valves are critical components in many industrial processes, handling fluids and chemicals that can lead to erosion, corrosion, and cavitation damage. Over time, this deterioration reduces efficiency and increases maintenance costs.

Benefits:

- Forms a protective layer that resists chemical attack and abrasion.

- Reduces friction and wear, leading to improved efficiency.

- Extends the lifespan of impellers, housings, and valve interiors.

By applying Devcon Brushable Ceramic Coating, industries can prevent premature failures and maintain optimal performance in fluid-handling systems.

2. Pipe and Tank Lining

Application:

Pipes and tanks that transport or store chemicals, slurry, or abrasive materials are prone to internal corrosion and scaling, leading to leaks, contamination, and costly repairs.

Benefits:

- Provides a chemically resistant and smooth lining.

- Prevents rust, scaling, and corrosion, especially in aggressive environments.

- Reduces material buildup, improving flow efficiency.

Industries such as oil & gas, water treatment, and mining can significantly benefit from this protective solution in their pipework and storage systems.

3. Heat Exchangers and Condensers

Application:

Heat exchangers and condensers operate under extreme conditions, frequently exposed to hot fluids, steam, and corrosive elements. Over time, this exposure can cause erosion and fouling, reducing heat transfer efficiency.

Benefits:

- Creates a smooth, non-stick surface that prevents deposits and fouling.

- Protects against thermal stress and corrosion.

- Improves energy efficiency and heat exchange performance.

By applying Devcon Brushable Ceramic Coating, industries can enhance the longevity and efficiency of their thermal management systems.

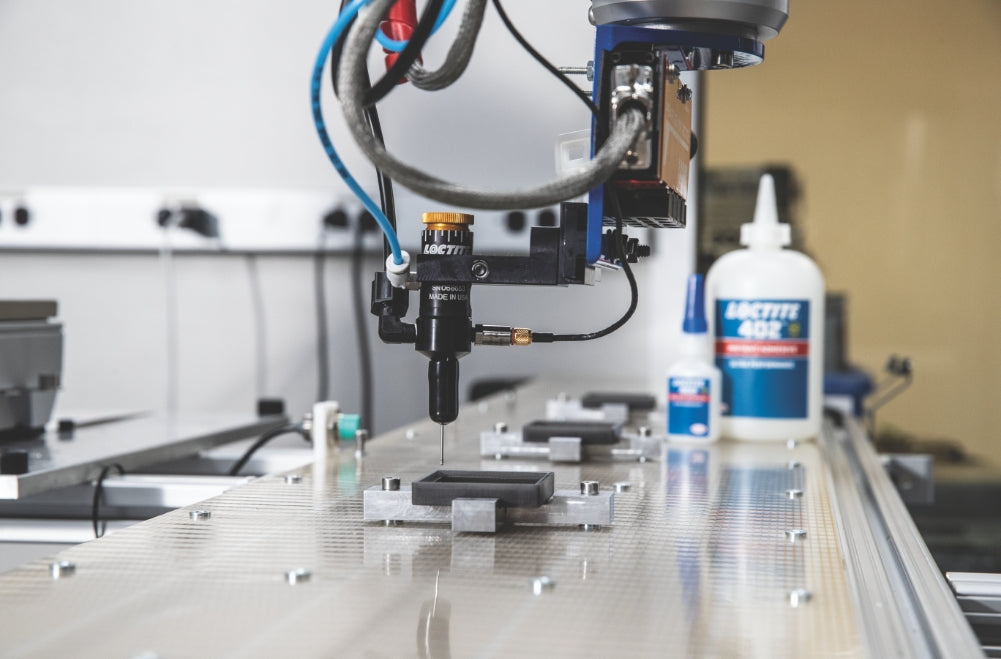

4. Industrial Machinery and Equipment

Application:

Mixers, blenders, and agitators in industries such as food processing, pharmaceuticals, and chemicals are frequently exposed to abrasive materials and chemical reactions that degrade metal surfaces.

Benefits:

- Prevents surface pitting, corrosion, and wear.

- Ensures a hygienic, smooth coating that is easy to clean.

- Reduces downtime and maintenance costs.

This coating provides a durable shield, ensuring smooth operation and compliance with safety and regulatory standards.

5. Marine and Offshore Applications

Application:

Marine structures, ship hulls, propellers, and ballast tanks are continuously exposed to saltwater, biofouling, and harsh weather conditions, leading to corrosion and performance degradation.

Benefits:

- Offers corrosion resistance against seawater exposure.

- Reduces marine growth and improves fuel efficiency.

- Extends the life of hulls, propellers, and structural components.

The use of Devcon Brushable Ceramic Coating in marine environments helps prevent costly repairs and improves vessel efficiency.

6. Chemical Processing Equipment

Application:

Reactors, storage tanks, and processing vessels in the chemical and pharmaceutical industries must withstand exposure to aggressive chemicals and extreme temperatures.

Benefits:

- Forms a chemically resistant barrier.

- Prevents metal surface degradation.

- Enhances safety by reducing contamination risks.

By applying this coating, companies can maintain structural integrity and regulatory compliance in their chemical processing operations.

Conclusion

Devcon Brushable Ceramic Coating is a versatile and effective solution for protecting metal surfaces in industrial applications. Whether used in pumps, pipes, heat exchangers, marine structures, or chemical processing equipment, this epoxy-based coating significantly extends the lifespan of critical components, reduces maintenance costs, and enhances operational efficiency.

Industries that implement Devcon Brushable Ceramic Coating benefit from improved performance, reduced downtime, and increased durability in their essential machinery and infrastructure. If you are looking for reliable protective coating, this solution is a valuable investment for your industrial needs.

发表评论

所有评论在发布前都会经过审核。

此站点受 reCAPTCHA 保护,并且 Google 隐私政策和服务条款适用。