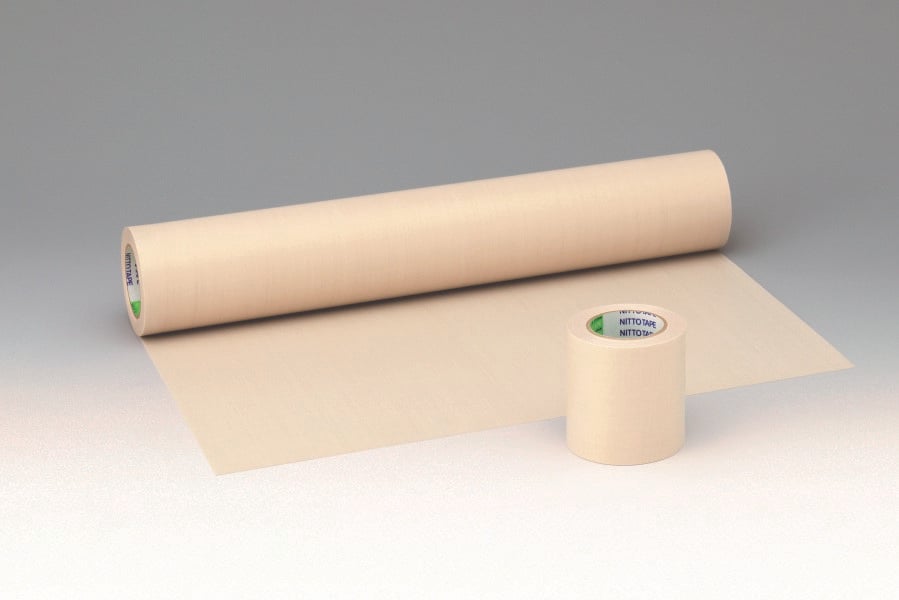

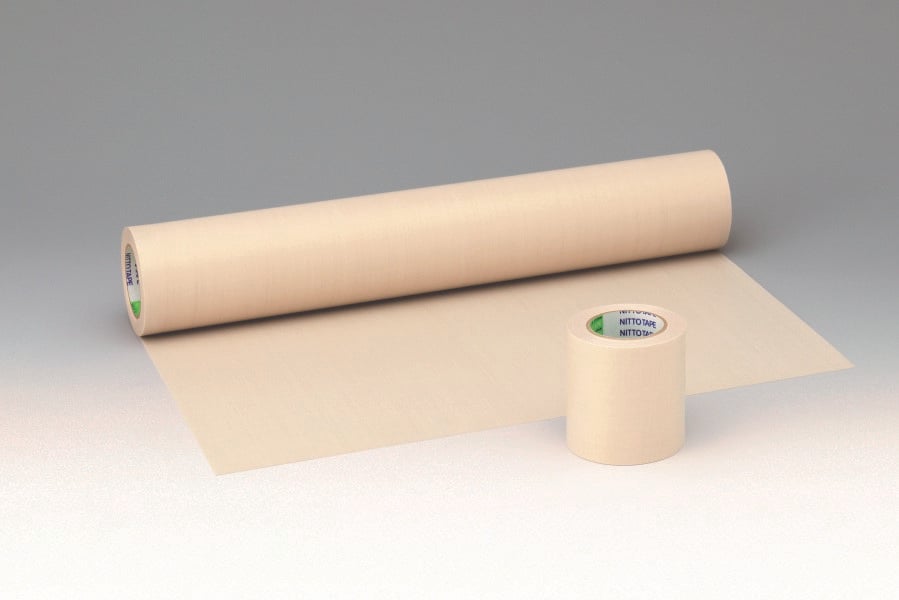

Fluoroplastic Saturated Glass Cloth NITOFLON No.970-2UL/No.970-4UL/No.9700UL

Keterangan

Read More

Read Less

Non-alkali glass cloth impregnated with PTFE and sintered.

NITOFLON No.970-2UL/No.970-4UL/No.9700UL consist of a non-alkali glass cloth base impregnated with polytetrafluoroethylene (PTFE) and sintered. Exhibits excellent features such as chemical resistance, electrical properties, weather resistance and non-adhesiveness.

Features

- Three types of different smoothness: No.970-2UL general type, No.970-4UL heavy impregnated type, and No.9700UL surface-smooth type.

- Polytetrafluoroethylene composite with stable molecular structure that is not affected by virtually all industrial chemicals or solvents.

- Available for continuous use in a wide range of temperature; from -100°C to 260°C. Along with the superior dimensional stability of the cloth base material at both high and very low temperatures, it also has superior thermal properties compared to other thermoplastics.

- Both dielectric constant and dielectric loss tangent are lowest and remain stable in a wide range of frencies.

- Superior resistance to weather, moisture, and contamination.

- Lowest static friction coefficient among all solid materials. It demonstrates unique self-lubricating property of lowering static friction coefficient as the load increases. With its non-adhesiveness and mold-releasing property, no adhesive substance attaches to it and makes mold-releasing easy when it comes into contact with adhesive substance.

Structure

*Adhesive type is also available.

Properties

| Property | Unit | Characteristic value | |||||||||

| No.970-2UL | No.970-4UL | No.9700 UL | |||||||||

| Base material thickness | [mm] | 0.05 | 0.10 | 0.13 | 0.05 | 0.10 | 0.13 | 0.05 | 0.10 | 0.13 | |

| Total thickness | [mm] | 0.07 | 0.12 | 0.17 | 0.08 | 0.13 | 0.18 | 0.08 | 0.14 | 0.18 | |

| Tensile strength | Lengthwise | [N/15mm] | 200 | 430 | 490 | 200 | 430 | 490 | 200 | 430 | 490 |

| Widthwise | 160 | 370 | 460 | 160 | 370 | 460 | 160 | 370 | 460 | ||

| Friction 8 coefficient | - | 0.08 | 0.08 | 0.10 | 0.08 | 0.08 | 0.10 | 0.08 | 0.08 | 0.10 | |

| Breakdown voltage | [kV] | - | - | - | 1.3 | 1.4 | 1.9 | 1.3 | 1.5 | 1.6 | |

| Volume resistivity | [Ω・cm] | - | - | - | 1016 | 1016 | 1016 | 1016 | 1016 | 1016 | |

[Remarks]

- *The above values are sample observed values, not the guaranteed performance.

Application

- For molding: mold-releasing sheets.

- For printing: drying screen-printing machines.

- For apparels: adhesive interlining belts.

- For food processing: heat sealers, frozen food transportation, defrosting belt and baking belt.

- For packing: shrink film packaging and side band sealing.

- For office equipments: paper conveyor belt of copiers.

Experimental video

Heat Resistance

Sliding Properties

Electrical Insulation

Chemical Resistance

Mold Release Properties

Weather Resistance

Fluoroplastic Saturated Glass Cloth NITOFLON No.970-2UL/No.970-4UL/No.9700UL

Harga penjualan$0.00

Harga normal (/)